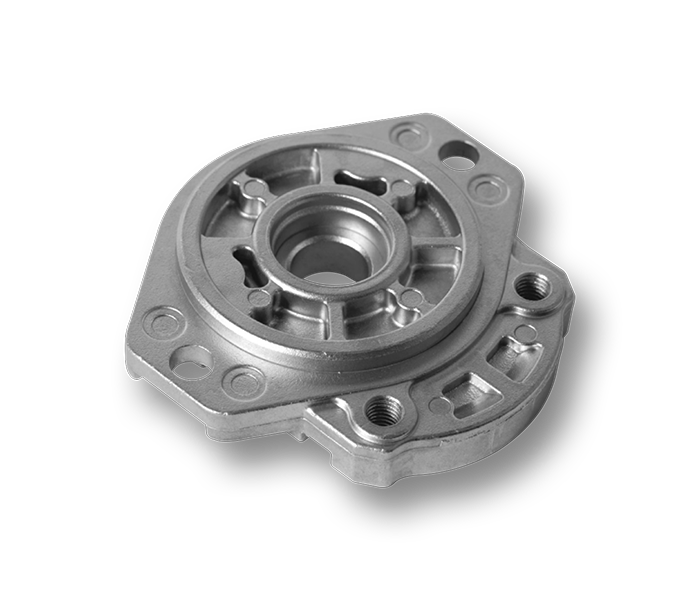

Aluminum

INNOVATION CAN BE SO LIGHT AND EASY. ALUMINIUM AT ITS BEST.

Aluminum is a material that is especially characterized by its low weight and excellent dynamic properties. Technical parts made of aluminum are up to 50% lighter in weight than the same parts made of steel or zinc, and can be recycled any number of times – 90% of all aluminum materials ever produced throughout the world are still in use..

General facts

Aluminum was first manufactured by the Danish researcher Hans Christian Ørsted in 1825. Industrial production was introduced in 1886 with the help of the electrolytic process still in use today; since that time, aluminum has become one of the most versatile and most widespread working metals. Due to its low weight and high strength that can be compared to steel, aluminum is an important material in automobile and machinery construction as well as in electrical engineering.

Although high amounts of energy are needed to obtain aluminum from bauxite, the necessary energy is mostly generated by water power and hardly emits any carbon dioxide that would pollute the environment. Aluminum can be easily separated from scrap and re-used without any quality losses using approx. 5%-10% of the original energy input only. We use primary and secondary aluminum for our die cast parts.